Green Manufacturing

Long-term Climate Change Goal Setting

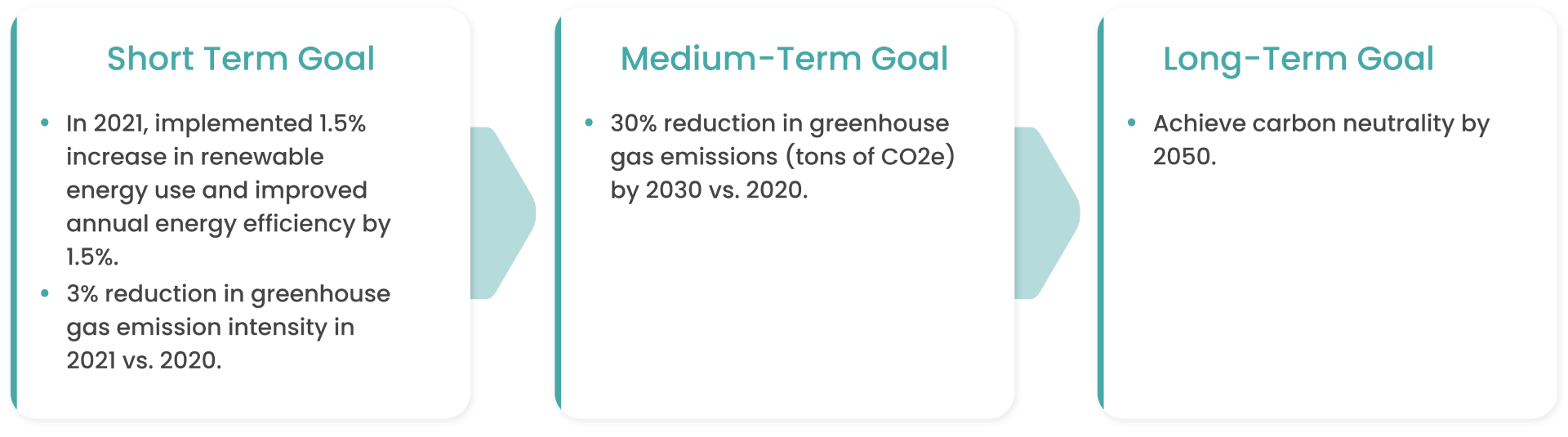

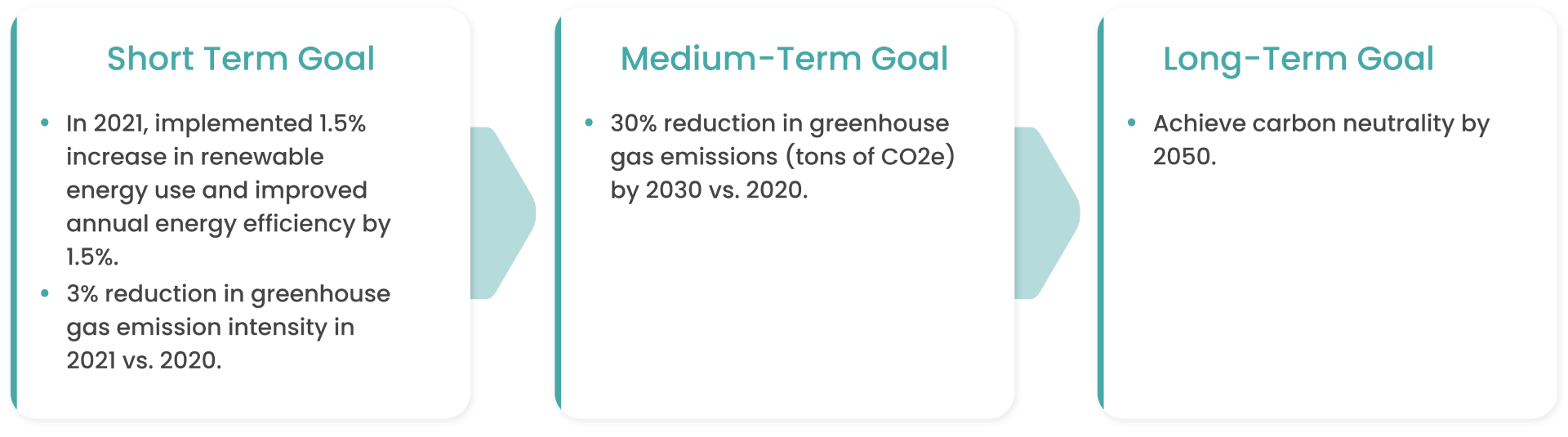

The government of Taiwan has aligned with the global consensus of attaining zero carbon emissions by 2050. At BenQ Materials, we have set short-, medium-and long-term checkpoints to do our part in achieving that goal. In the short term, we will invest in new technologies and equipment, such as artificial intelligence (AI), to improve the efficiency of production equipment. These include energy-and water-saving resources, as well as increased recycling with the aim of achieving an annual efficiency increase of 1.5%.

At the same time, we have since 2020 installed solar panels on the roofs of our factories in Taiwan and China. We expect to complete these installations in all our factories by 2025, significantly boosting renewable energy supply. To meet medium-term goals, we will purchase green power and green power certificates to achieve a 30% reduction in greenhouse gas emissions (tons of CO2e) by 2030 compared to 2020. In the long term, we will continue to expand access to renewable energy and reach the goal of carbon neutrality by 2050 through carbon trading, research on carbon capture technologies, and the like.

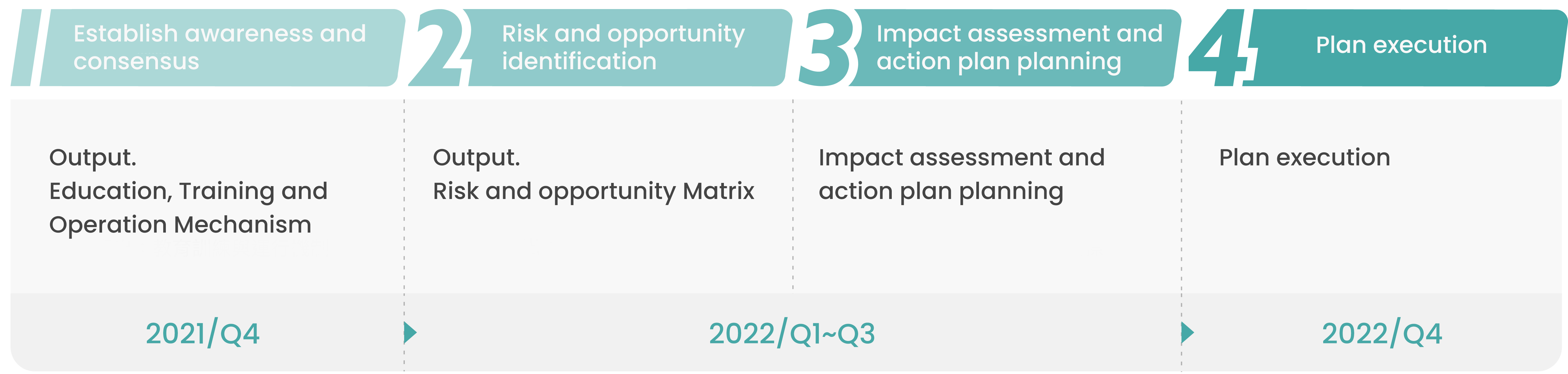

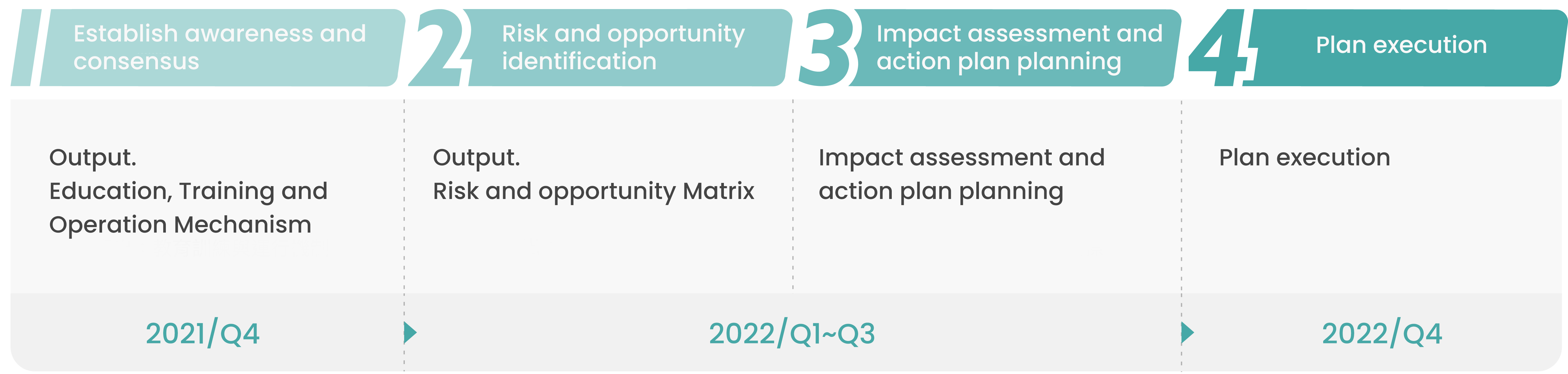

TCFD Promotion Plan and Schedule

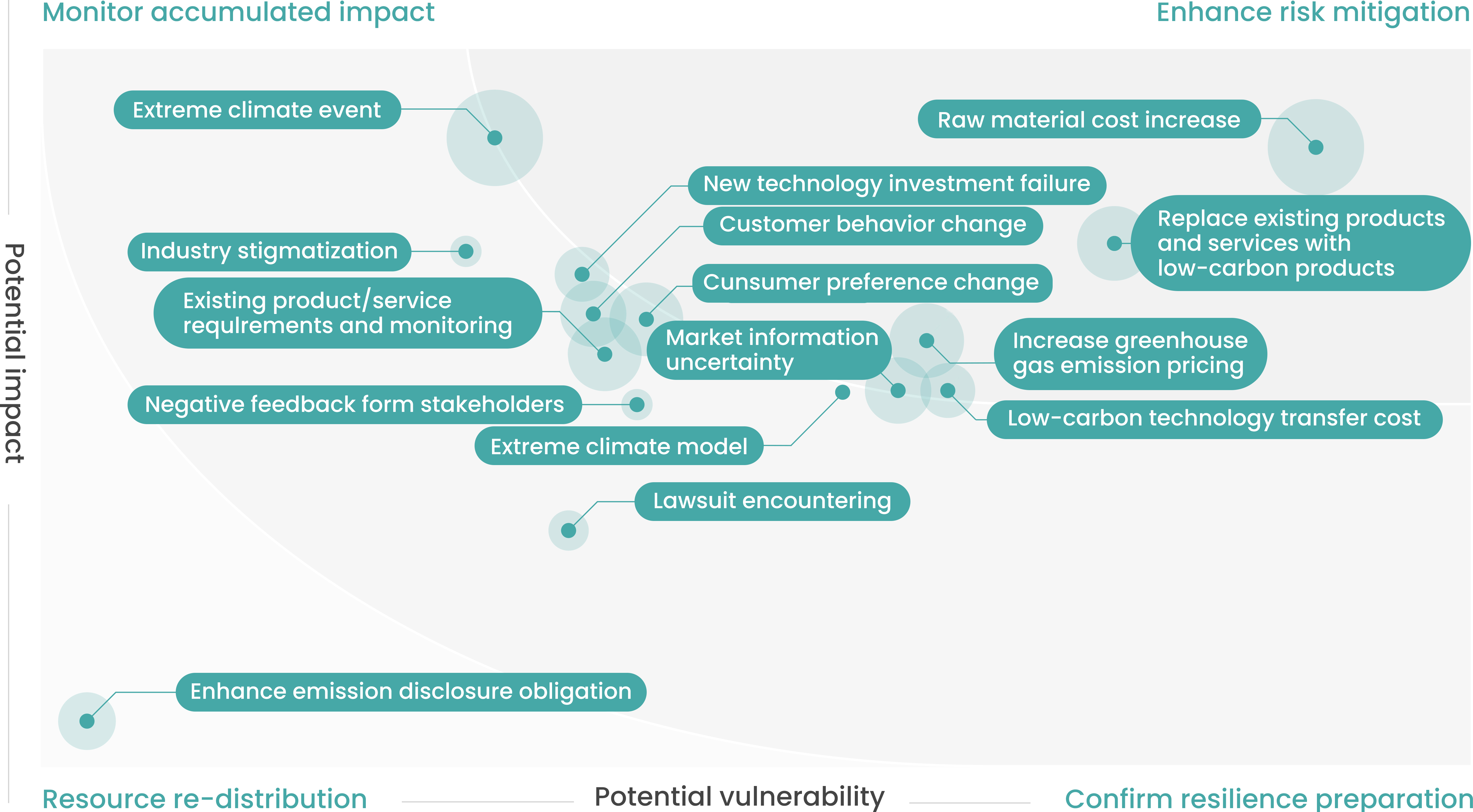

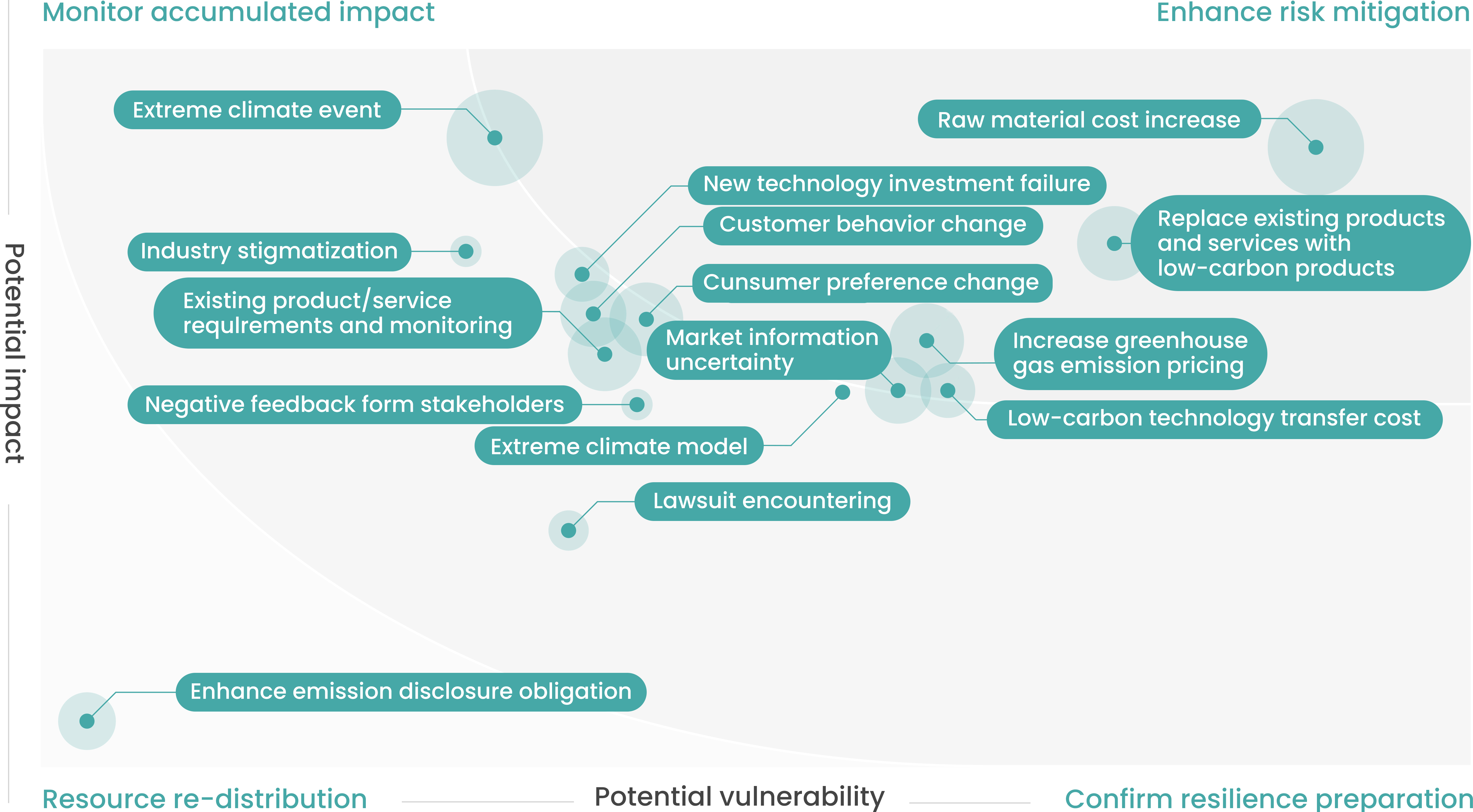

Risk Assessment

Note:

Potential vulnerability: The preparation level or adaptability of BenQ Materials for such risk item (X axis: when the value is greater, it means the preparation level is lower, and the adaptability is lower)

Potential impact level: The impact level on the operation of BenQ Materials when such risk item (Y axis: when the value is greater, it means its impact level on the operation is higher)

Probability of occurrence: The probability of occurrence of such risk item in 10 years (size of bubble: when the size is greater, it means its occurrence probability is higher)

Greenhouse Gas Management

As the effects of global warming become more severe, BenQ Materials has since 2008 established a complete inventory of greenhouse gas emissions from our manufacturing sites with reference to the requirements of the Organizational Greenhouse Gas Emissions (ISO 14064-1) and the Greenhouse Gas Inventory Protocol (GHG Protocol). We conduct annual greenhouse gas inventories and third-party verification. Emissions inventory results from our factories passed ISO 14064-1:2018 third-party verification in 2018. The power usage in our factories is the primary source of energy consumption in terms of fuel (natural gas, gasoline and diesel). According to the verification results of the new version of greenhouse gas emissions, it is set as the base year for emissions.

There are two significant sources of greenhouse gas emissions at BenQ Materials. The primary source is carbon dioxide generated during the process of power generation from purchased electricity required for operations. The second is greenhouse gases emitted by gas and gasoline used in internal operations. Purchased electricity emission sources account for 58.76% of our overall emissions. For the emissions evaluation of Scope 3, an assessment of the significance of emissions based on ISO 14064-1 standard was conducted. The results of the assessment included out-of-Scope 1 and 2 fuel and energy-related activities, upstream transportation and distribution (Yunlin Tech Plant only), and waste generated from operations as the items to be examined at this stage.

Greenhouse gas emissions (Scope 1, 2, and 3) in 2021 were 68,979.12 tons of CO2e, an increase of 1,916.99 tons (+2.86%) compared to 2020. The intensity of greenhouse gas emissions decreased by 6.08%, mainly due to revenue growth of 9.51%. When the greenhouse gas intensity (Scope 1 and 2) is analyzed, reductions yearly have been recorded since 2017. The unit intensity in 2021 was 3.61 (tons of CO2e/NT$ million), a decrease of 5.76% vs. 2020 and a drop of 22.17% from 2017. The results of the 2021 inspection were verified by a third party, covering all operating sites (factories in Taiwan, Suzhou, Wuhu).

To continuously reduce greenhouse gas emissions of products, BenQ Materials will evaluate the life cycle of products and implement a carbon footprint system to assess the greenhouse gases associated with products and services and formulate appropriate measures to reduce carbon emissions so that it can play a greater role in combating climate change. In 2021, the company selected the Textile and Polarizer Business Group to implement new product carbon footprint inspection guidance, with the assessment completed in 2022.

The government of Taiwan has aligned with the global consensus of attaining zero carbon emissions by 2050. At BenQ Materials, we have set short-, medium-and long-term checkpoints to do our part in achieving that goal. In the short term, we will invest in new technologies and equipment, such as artificial intelligence (AI), to improve the efficiency of production equipment. These include energy-and water-saving resources, as well as increased recycling with the aim of achieving an annual efficiency increase of 1.5%.

At the same time, we have since 2020 installed solar panels on the roofs of our factories in Taiwan and China. We expect to complete these installations in all our factories by 2025, significantly boosting renewable energy supply. To meet medium-term goals, we will purchase green power and green power certificates to achieve a 30% reduction in greenhouse gas emissions (tons of CO2e) by 2030 compared to 2020. In the long term, we will continue to expand access to renewable energy and reach the goal of carbon neutrality by 2050 through carbon trading, research on carbon capture technologies, and the like.

TCFD Promotion Plan and Schedule

Risk Assessment

Note:

Potential vulnerability: The preparation level or adaptability of BenQ Materials for such risk item (X axis: when the value is greater, it means the preparation level is lower, and the adaptability is lower)

Potential impact level: The impact level on the operation of BenQ Materials when such risk item (Y axis: when the value is greater, it means its impact level on the operation is higher)

Probability of occurrence: The probability of occurrence of such risk item in 10 years (size of bubble: when the size is greater, it means its occurrence probability is higher)

Greenhouse Gas Management

As the effects of global warming become more severe, BenQ Materials has since 2008 established a complete inventory of greenhouse gas emissions from our manufacturing sites with reference to the requirements of the Organizational Greenhouse Gas Emissions (ISO 14064-1) and the Greenhouse Gas Inventory Protocol (GHG Protocol). We conduct annual greenhouse gas inventories and third-party verification. Emissions inventory results from our factories passed ISO 14064-1:2018 third-party verification in 2018. The power usage in our factories is the primary source of energy consumption in terms of fuel (natural gas, gasoline and diesel). According to the verification results of the new version of greenhouse gas emissions, it is set as the base year for emissions.

There are two significant sources of greenhouse gas emissions at BenQ Materials. The primary source is carbon dioxide generated during the process of power generation from purchased electricity required for operations. The second is greenhouse gases emitted by gas and gasoline used in internal operations. Purchased electricity emission sources account for 58.76% of our overall emissions. For the emissions evaluation of Scope 3, an assessment of the significance of emissions based on ISO 14064-1 standard was conducted. The results of the assessment included out-of-Scope 1 and 2 fuel and energy-related activities, upstream transportation and distribution (Yunlin Tech Plant only), and waste generated from operations as the items to be examined at this stage.

Greenhouse gas emissions (Scope 1, 2, and 3) in 2021 were 68,979.12 tons of CO2e, an increase of 1,916.99 tons (+2.86%) compared to 2020. The intensity of greenhouse gas emissions decreased by 6.08%, mainly due to revenue growth of 9.51%. When the greenhouse gas intensity (Scope 1 and 2) is analyzed, reductions yearly have been recorded since 2017. The unit intensity in 2021 was 3.61 (tons of CO2e/NT$ million), a decrease of 5.76% vs. 2020 and a drop of 22.17% from 2017. The results of the 2021 inspection were verified by a third party, covering all operating sites (factories in Taiwan, Suzhou, Wuhu).

To continuously reduce greenhouse gas emissions of products, BenQ Materials will evaluate the life cycle of products and implement a carbon footprint system to assess the greenhouse gases associated with products and services and formulate appropriate measures to reduce carbon emissions so that it can play a greater role in combating climate change. In 2021, the company selected the Textile and Polarizer Business Group to implement new product carbon footprint inspection guidance, with the assessment completed in 2022.